Want to improve supply chain efficiency? Keep reading.

Managing logistics can be exhausting – and at times even impossible to do manually. This includes a myriad of processes from planning to execution. We’re talking transportation, inventory, employee management, warehousing, and more.

What’s the easier and more efficient way to handle logistics with all it entails? The answer is data-driven logistics powered with technology. Or simply put – a digital supply chain!

What is a digital supply chain and how do they work?

A digital supply chain is a system of different technologies that manage all processes. It includes every aspect of the supply chain from production and transformation to logistics. Thanks to the advances in technology, a digital supply chain is more than viable. We have access to a wide range of digital technologies that can significantly improve the efficiency of the supply chain and so, why not use them to our benefit?

The global digital supply chain market is projected to reach over $13 million by 2030 compared to less than $4 million in 2020, which equals a CAGR of 13.2%. This considers advanced analytics, digital platforms, cloud-based management solutions, as well as IoT, AI, robotics, and much more. The list only grows every day.

If you’re seeking a way to improve supply chain efficiency, the answers lie in technology. In this article, we will elaborate on data-driven logistics and discuss how to leverage technology for your benefit.

Benefits of a data-driven supply chain

Wondering what a data-driven supply chain strategy can do for you? Take a look at these benefits:

- Reduce inventory costs

- Increase operation efficiency

- Improve customer service

- Minimize logistical issues

An optimized supply chain can do this and beyond, which is why over the past decades, more and more companies have started applying technology to various work functions.

Of course, the success of your supply chain will depend greatly on what technology you leverage.

Using the right software for proper supply chain management

Different technologies and software solutions can provide you with a diverse set of features and tools. Let’s say that your company handles equipment or transportation. You need to handle warehousing, outsourcing, and transportation. An equipment management software will do the following:

- Manage in-house and outsourced maintenance

- Keep track of equipment and power tools

- Create notifications and reports

- Track fleet fuel

- Manage vehicle inspections

- Keep track of equipment activity

Different technologies come with different capabilities. You can leverage the more feature-rich options to automate and keep track of many of your company’s supply chain elements. For instance, an equipment management software is not just useful for managing the equipment. It can also improve communication with your employees and vendors.

By choosing the right technology and implementing a data-driven strategy, you can achieve the following and more:

- Predict and prevent problems before they cost your company a fortune

- Adjust and overcome unexpected delivery obstacles and other changes in the supply chain

- Identify new production opportunities

- Save unnecessary expenses by avoiding errors

- Maintain a smart inventory that changes based on customer demand

6 Ways to leverage technology to improve supply chain efficiency

Since there are so many processes in logistics, what exactly can you use technology for? Let’s take a look at some of your options.

1. Data-driven planning

Technology gives you access to data that you can use to plan your logistics and forecast what you’ll need in the future.

Data analytics can help you analyze demand patterns, customer needs and preferences, inventory levels, market conditions, delivery times, pricing strategies, and much more. In return, you’ll get a reduction of costs, risks, and waste.

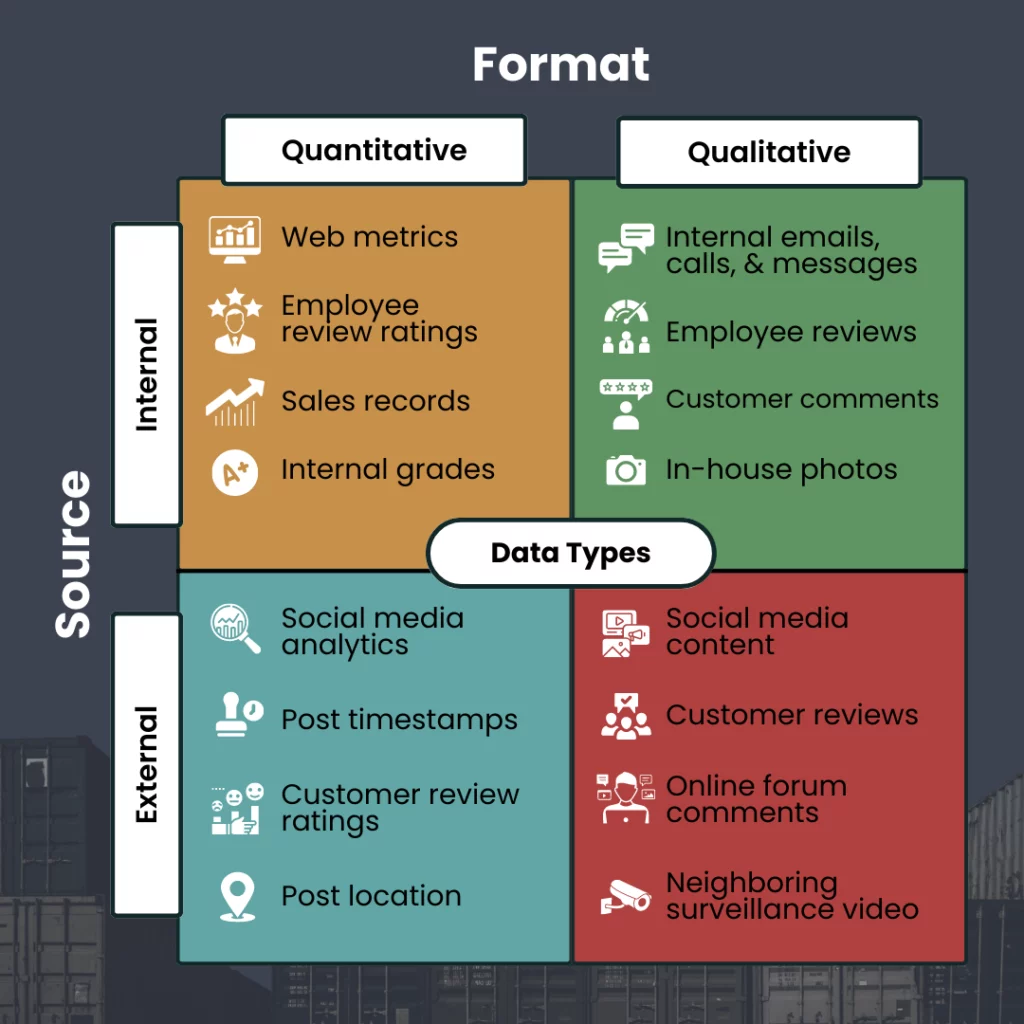

Here’s a table to show the types of data to consider.

To make all of this happen, you need to make use of two sets of data – internal and external.

Direct your main focus towards internal data. Technology will allow you to collect all functional data that your company possesses, from all departments that take part in the supply chain.

Then, support your decisions on external data. There are plenty of fluctuations in the supply and logistics market. Today, when inflation is at its peak, customer spending changes easily. To boost the resilience of your supply chain, try to leverage demographic data, current trends, and inventory data.

2. Real-time tracking and visibility

Another way to use technology is to boost your real-time visibility as well as the tracking of your logistics assets and processes. Technologies like cloud computing, GPS, and sensors can give you access to your vehicles, shipments, and your drivers – all in real-time.

Such technologies make inventory management easier than ever, both in small and large companies. This is especially important when you’re keeping track of numerous vehicles and shipments, and have plenty of employees or bulk of inventory scattered around.

Simpler technology such as report generators, tracking tools, and dashboards are very useful for this, too. They can help you visualize everything and improve your operational compliance and efficiency.

Not so long ago, the biggest challenge in supply chain management was real-time visibility. It was near-impossible to keep track of where every driver or vehicle is. It was a hassle to figure out the physical location of each inventory piece. Today with IoT sensors and RFID tags, this is simpler than ever. Plus, errors are minimized if not eliminated altogether.

3. Predictive analysis

Imagine having all that data on your hands at all times. You’ll know where everyone and everything is in real-time. This information is not only useful for compliance or reporting – it’s useful for prediction, too.

Real-time data will allow you to accurately forecast:

- Potential bottlenecks

- Demand patterns

- Inventory levels and changes

- Future expenses

- Opportunities for growth

4. Automation and robotics

Automation is a popular way to optimize a supply chain these days. Many companies integrate technology to automate their systems and processes. By using artificial intelligence, machine learning, robotics, blockchain, and other modern technologies, you can automate many of the repetitive tasks like picking, loading, packing, invoicing, sending reminders, and more.

There are many ways to automate data to boost your supply chain efficiency. For instance, process automation or RPA can streamline the most repetitive tasks like invoice verification, order processing, inventory reconciliation, etc.

Today, you’ll rarely find a big logistics company sending invoices on paper, manually typed after many calculations. They all gather data using technology, and often even automate the tools they have to send out invoices on their own.

A warehouse automation solution, for instance, can accelerate the fulfillment of orders. You can use automated picking systems or even robotic arms. A proper technology stack can help a business squeeze a huge amount of products in a limited space and maximize efficiency and profits.

Automation will allow you to share performance metrics such as order status with your employees, or lot tracking and order processing times with shareholders.

Automation will help you keep track of all the inventory you have – and its location. The 2020 Supply Chain Survey of US Retailers found that 67% of consumers require inventory visibility across online and mobile stores.

By automating the supply chain, you can avoid errors and give consumers real information about your inventory across stores.

5. Blockchain for a boost in transparency

Logistics companies constantly juggle sensitive data and the risks are enormous. With blockchain technology, they can finally create a secure, immutable record of transactions by keeping the data safe. This is vital in industries where compliance and authenticity are of the highest importance, such as pharmaceuticals or companies dealing with food.

Blockchain facilitates secure collaboration and data sharing among partners in the supply chain. This can go a long way to reduce the risk of fraud.

6. Risk management

Finally, technology can assist in scenario planning and risk management. Organizations can use it to mitigate any potential disruptions.

For example, using a supply chain risk management platform will visualize data and analyze it to help you monitor the risks across your network. When you have it all in your eyesight, you can respond swiftly when an unexpected event takes place. There will be contingency plans for vulnerabilities that you prepared for a long time ago, giving you a competitive edge.

Modeling tools and simulation tools can help you plan for scenarios. You can evaluate different strategies and test them before they cost your company time and money. Finally, you’ll have the most promising solution to use.

The competition in logistics is grand today, so companies often hardness technology to identify vulnerabilities. They use real-time visibility, blockchain, predictive analysis, automation, risk management tools, and much more – all to prepare for what’s to come next.

Have you adopted logistics technology solutions yet?

If the answer is yes, share your experience with it in the comments. If the answer is no, or you have only leveraged logistic technology to a small extent, you should consider expanding on this.

It’s not always easy to start something new and there might be costs involved, but innovation is the only way to thrive in a competitive and demanding market. The benefits are undeniable and include improved efficiency, enhanced collaboration, better customer service, and higher profits. Go on, consider logistics technology, you won’t regret it.

Acumen Connections